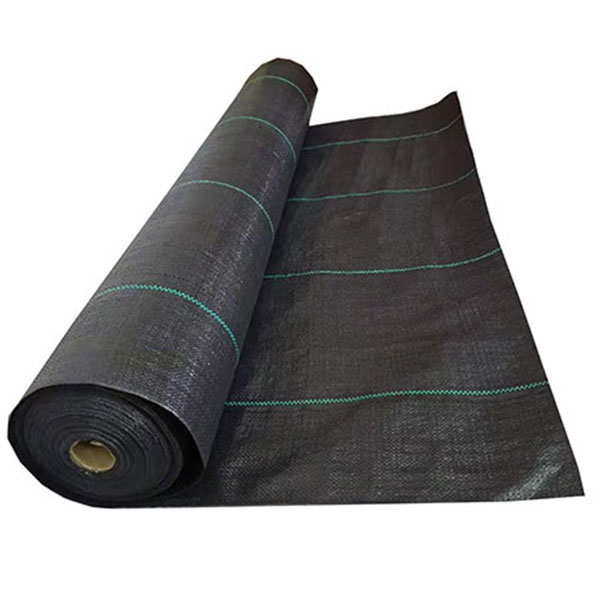

PP/PET agịga ntụmadị geotextile akwa

| Ibu | 100-500 gm |

| Obosara | 0.3m-6m |

| Ogologo | 10m-100m ma ọ bụ dị ka gị chọrọ |

| Agba | Black, White, isi awọ, odo ma ọ bụ dị ka arịrịọ gị |

| Ihe onwunwe | 100% Polypropylene / Polyester |

| Oge Mbuga ozi | 25 ụbọchị mgbe ịtụ |

| UV | Na UV kwụsiri ike |

| MOQ | 2 tọn |

| Usoro ịkwụ ụgwọ | T/T, L/C |

| Nkwakọ ngwaahịa | Dị ka gị chọrọ |

Nkọwa:

A na-eji polyester ma ọ bụ polypropylene mee agịga apịghị ọkpọ n'ebe a na-enweghị usoro wee tụọ ya ọnụ site na agịga. Geotextiles nwere ezigbo permeability na iguzogide nrụrụ, nke na-enye ohere itinye geotextiles n'ọtụtụ ebe na ọrụ obodo maka nkewa, nzacha, nkwalite, nchekwa na drainage.

PET Nonwoven agịga Punched Geotextiles Fabric bụ agịga anaghị kpara akpa polyester paving geotextiles, nke na-enye enyemaka nrụgide, mkpuchi mmiri ma belata ọrụ mgbawa na-egosipụta n'okporo ụzọ awara awara ọhụrụ na nke dị adị.

Ezubere maka mba ndị nwere oke ọnọdụ ihu igwe n'uche, ngwaahịa a emeela ọtụtụ afọ nke nnwale na ndozi iji nye arụmọrụ kachasị mma n'ozuzu ya.

Njirimara pụrụ iche nke Geotextiles ndị a na-enye mkpuchi mmiri na nchekasị nke usoro pavement. Okpomọkụ dị elu nke Polyester (PET) na-eme ka o doo anya na akụrụngwa geotextiles adịghị emetụta ngwa nke bitumen na-ekpo ọkụ ma ọ bụ asphalt.

Ngwa:

1. Nzacha

Iji dowe ụmụ irighiri ihe achọrọ mgbe mmiri na-esi na obere ọka na-aga n'ụdị oyi akwa na-enweghị isi, dị ka mgbe mmiri na-esi na ala aja na-asọba n'ime ebe a na-ekechi gravel Geotextile.

2. Nkewa

Iji kewaa okpukpu abụọ nke ala nwere ihe anụ ahụ dị iche iche, dị ka nkewa nke gravel okporo ụzọ site na ihe ndị dị n'okpuru ala.

3. igbapu mmiri

Iji kpochapu mmiri mmiri ma ọ bụ gas site na ụgbọ elu nke ákwà ahụ, nke na-eduga n'ịgbapụta ma ọ bụ ikuku nke ala, dị ka oyi akwa ikuku gas na okpu ala.

4. Nkwalite

Iji meziwanye ikike ibu ibu nke ihe owuwu ala akọwapụtara, dị ka nkwado nke mgbidi ejigide.